other Products

weecoat-07

Nanotechnology for marine industry

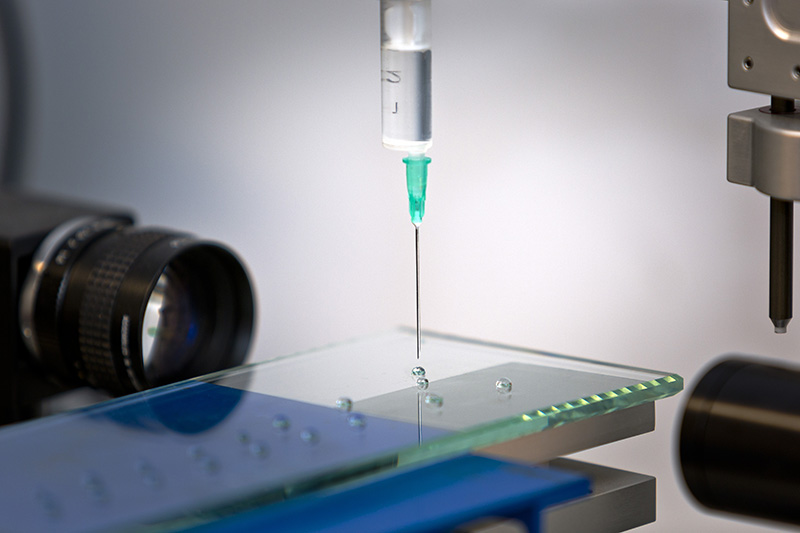

Weecoat07 is an anti-adherent coating with hydrophobic, oleophobic and rust-resistant properties.

Without weecoat

With weecoat

Propellers treated with Weecoat07 maintain their original design without adhesions, achieving design benefits throughout the useful life of the propeller.

The problem: Marine Biofouling

In just a few months, a ship’s propeller can be completely covered in marine organisms.

|

Heat resistence |

-60oc to 350oc |

|

Appearance |

Homogenous and without impurities/contaminations |

|

Coating thickness |

2-4μm of thickness |

|

Easy to clean |

Good non-stick properties getting 99% of the maximum possible score |

|

Durability – Abrasion resistance |

High durability and abrasion resistance, losing only 2% of it’s non-stick performance after 30,000 cycles of abrasion-cleaning combined. |

|

High heat shock resistance |

The coating has good resistance to thermal shock and also protects the metal against discoloration produced by it arround 90/95% |

|

Hardness – Scratching resistance |

More than 9H hardness |

|

Corrosion resistance |

Delay of the first corrosion by more 75% in stainless steel and 1100% in aluminium |

|

Accelerated aging |

No change or deterioration observed after 1700h in accelerated aging chamber |

|

Mechanical resistance |

Impact resistance: ISO6272-1:2012 OK Resistance to bending (1.5-2T): ISO1519:2011 OK Drawing rsistance: ISO1520:1999 OK Shear strenght OK |

- Good adhesion and long-lasting effect Improves slippage in water

- Easy cleaning

- Abrasion resistance

- Scratch resistance

- Corrosion resistance

- High temperature resistance

- Anti-rust

- Hydrophobic

- NonStick

- Reduces cavitation

- Uncolored

- Reduces noise vibration

- Reduces fuel consumption

- Optimal speed close to the maximum speed Reduces maintenance costs

- Improves the life of the entire propulsion system

Weecoat07 is the best anti-biofouling solution for propeller care.

Certifications approved

Impact resistance

Bend test

UNE-EN ISO 1519:2011

Cupping test

Cross-cut test

ASTM D3359

Clasification 0/5B

Wet-scrub test

10 years of self life

Scratching test

More than H9 hardness

Accelerated aging test

Shear Strength test

Request a quote

AMERICAS

phone

![]() +52 1 669 273 3007

+52 1 669 273 3007

M +351 918 274 270

leonardo@weeprop.com

europe

phone

+34 687 897 319

pablo@weeprop.com